Nowadays, most of the maintenance work is done on energized lines since it is economically more beneficial, does not disrupt consumers, and is safer for workers in some sense. Linemen doing live work (LW) are well-trained, equipped with personal protective equipment depending on the voltage level and use live working techniques. During high voltage LW, it is a conductive suit, also called bare-hand suit, as they are on the same potential level as the energized part they are working on, while medium and low voltage LW include insulation from the live parts. Therefore, live working is not only a better option economically but also quite safe for linemen. However, maintenance and reparation sometimes cannot be done on energized lines (e.g., replacing conductors). Therefore, lines must be de-energized to execute these procedures.

The main problem with working on a de-energized line is that energized parts can be nearby. These parts create an electromagnetic field around them; the higher the AC voltage, the higher the electric field intensity is. Additionally, the higher the AC current, the higher the magnetic field intensity is. Both fields’ intensities depend on the geometry, such as the distance from the energized parts (the source of the AC voltage and current); the further they are, the less intense the fields are. Any conductor near the energized electrical AC installations is induced with a non-zero electrostatic potential and electromotive force (EMF).

The risk of AC induction is especially high on double-circuit power lines where linemen work on the passive side while the other side is in operation and in powerline or railway line crossings where the de-energized lines are crossed by a different line that is normally operating.

In practice, voltage and current seem to appear on the de-energized line, where workers do not expect either. AC induction can occur through capacitive coupling (e.g., when a conductive object is positioned within the energized AC line’s electric field, a simple capacitor is created between the conductive parts) or via inductive coupling, typically through extended conductive loops, including the ground.

A possible solution against induction could be grounding the de-energized overhead line or equipment, reducing the electric field hazard if a very low resistive ground source (10 Ω or less) is used. If the de-energized line is not grounded at either end, it is unprotected from being accidentally energized. AC induction is a huge risk for workers since they do not expect voltage rise or current on the de-energized parts. In case of an error, if the currents due to electric shock exceed the let-go value, the consequences can be the inability to decouple from the electric circuit, asphyxia, unconsciousness, body burns, or even death.

Linemen should be protected against electric shock due to accidental touch of two different potentials (one usually being ground potential). Therefore, a special conductive suit was developed to minimize lethal faults due to AC induction. Several laboratory tests were performed to test the suit’s conductivity and also the suit’s resistance to heat, as high currents can heat the fabric noticeably. The induction suit was specifically made to protect against the electric shock of induced voltage, as it prevents the current through the worker’s body from exceeding 6 mA (let-go limit) while the induced current flows through. Like other conductive suits, the clothing acts as a Faraday cage, shunting most of the fault current. The main aim of developing the suit was to increase workers’ safety during vicinity work.

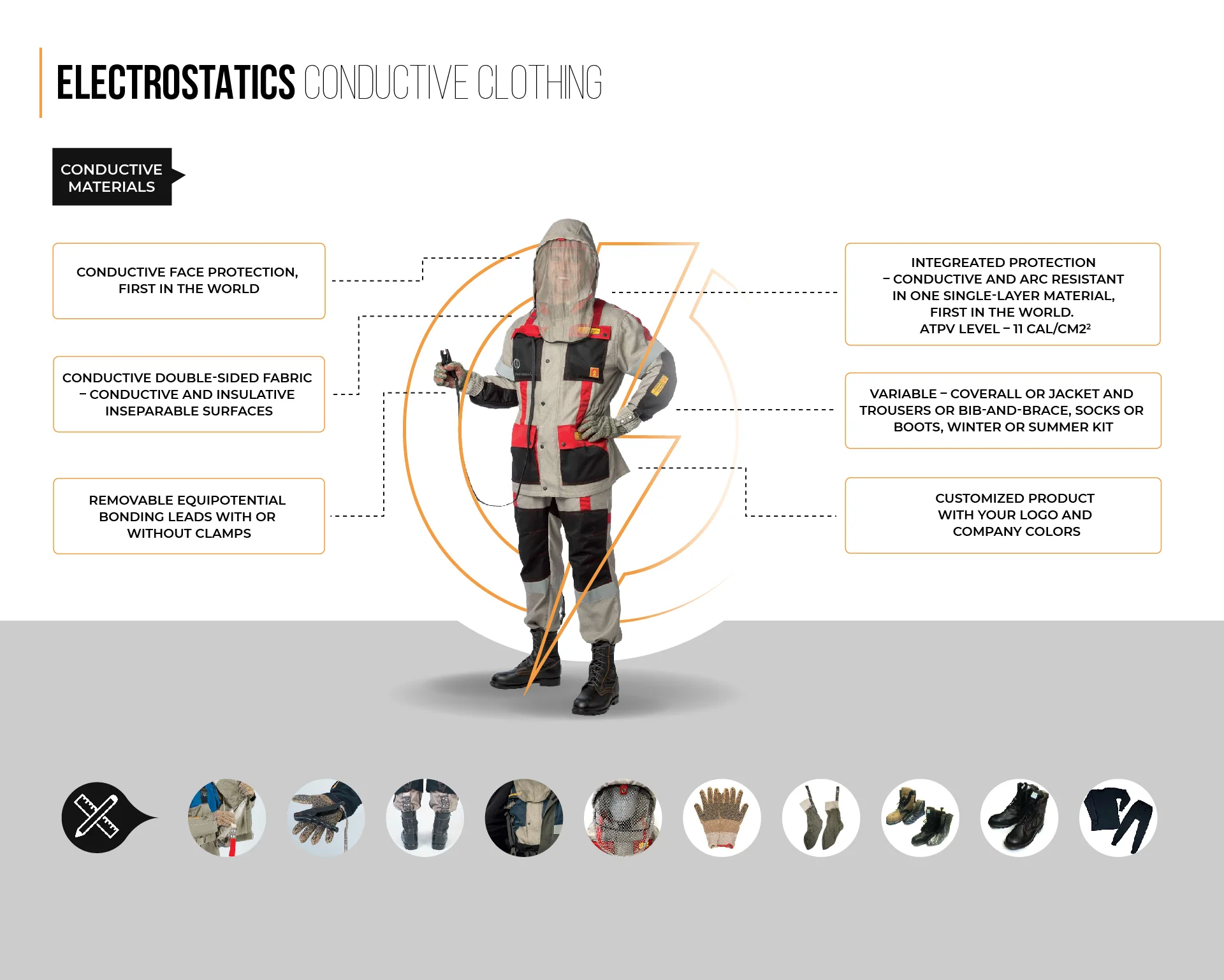

The suit consists of several parts a conductive garment and other conductive component parts such as gloves, boots, and socks. The garment can be a single-piece set (a coverall with a hood or headcover) or a two-piece set (jacket with a hood and bib-and-brace or trousers). The protective set includes an upper layer that provides protection against thermal hazards of an electric arc and ignition caused by electric discharges, a highly conductive band that has an electric resistance not more than 0.1 Ω/m and can shunt currents up to 50 A and 30 sec without any damage and a conductive double-side fabric which combines two inseparable surfaces: a conductive part (steel-silver) and an insulating part (meta aramid-FR viscose) that is closer to the human body. The electric resistance of the conductive surface of the fabric is not more than 2 Ω. As said before, the metallic fabric takes most of the induction current away from the worker.

Overall, this set offers protection against the electric field of industrial frequency, electrical discharges while bare-hand working with live parts, electric shock of induced voltage, and thermal hazards of electric arc. Every conductive component of the suit is connected by equipotential bonding leads (e.g., between the jacket and the gloves, jacket and the bib-and-brace or trousers, bib-and-brace or trousers and the boots or socks).

As with any conducive clothing, the induction suit’s technical condition should be tested regularly: an acceptance test before putting it into operation, periodic testing during the lifetime, and testing after washing or dry cleaning. The control not only consists of visual inspection (e.g., looking for breakage of the material or making sure the integrity of the bonding leads is still intact) but also measurement of the electric resistance of the conductive elements.

At Electrostatics Ltd., we are working on developing our conductive clothes in light of the latest research findings. We continuously enhance them from ergonomic and regulatory perspectives. With our garments, we ensure safe and efficient bare-hand live work.

We are proud that our products can contribute to safe work, network operation, and fewer power outages worldwide.

For more information on Electrostatics conductive clothing visit our product page!